Materials Used in Model Airplanes and Fixed-wing UAVs are indispensable. Almost the building blocks of flight dynamics, these materials directly affect the performance of the aircraft. With the appropriate choice of material, airplanes can soar like a bird in the air and give the user a great pleasure during the flight. The material you will use is very important when designing or making scale models yourself. In this article, we will talk about the materials used in the construction of radio controlled (rc) airplanes.

- Balsa

- Styrofoams (Foam)

- Filament

- Carbon fiber

- Fiber glass

1.Balsa One of the materials used in model airplanes and fixed-wing UAVs is: Balsa wood. It is obtained from balsa trees. It is the traditional building material used in the model airplane hobby in ancient times. This material provides a great advantage to airplanes thanks to its lightness and easy processability. Model airplane construction with balsa is literally an art. So it takes time and experience. Airplanes made of balsa can be equipped with two- or four-stroke explosive electric engines and this adds a special feature to balsa. We can cut the balsa with a utility knife or with cnc laser machines.

2.Styrofoam (foam) Foam is an indispensable material for radio-controlled airplanes. It is highly preferred by users because it is light, durable and inexpensive. There are different types according to its mass, density and durability. Radio control is recommended for beginners in the airplane hobby because of its low cost. Some types of styrofoam can be made more durable with fiber glass and coatings. The wings of styrofoam airplanes should be reinforced with spar. We can cut the styrofoam with the help of hot wire with a utility knife or 2d hot wire machine or 3d spincant cnc.

- Epo (expanded polyolefin)

- Epp (Extended Ploystren Foam)

- E9ps (expended Poystyrene)

- Depron-photoblock

- Epo (expanded polyolefin)

- Xps Extruded Polystyren

a) Epo (expanded polyolefin)

It is called expanded polyolefin and is a lightweight and durable material used in airplanes and fixed-wing UAVs. They have a better surface coating than other styrofoam types. This gives it an aerodynamic surface. If desired, the durability of the aircraft parts can be increased with glass fiber fabric and epoxy. Many companies use the raw material of epo and instead of shaping the styrofoam by cutting it, they produce it by pouring it into molds according to the parts of the aircraft to be made. Note: In hand thrown planes, abrasion of the styrofoam may occur as a result of the styrofoam rubbing against the ground during landing. In order to prevent this abrasion, the lower part can be covered with fiberglass.

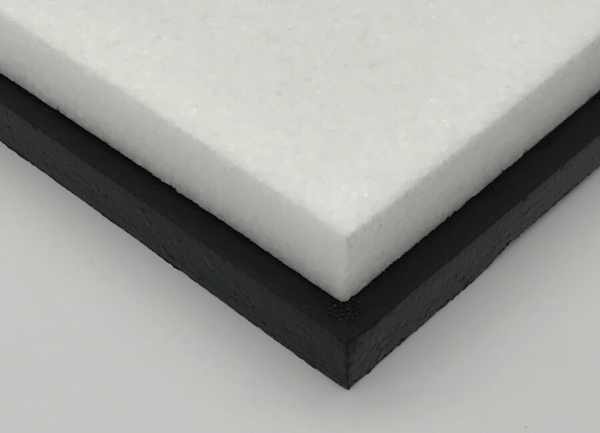

b) Epp (extended polystyrene) is called extended polypropylene. It is from the polypropylene family of thermoplastics .It has higher durability than epo. It has high elasticity and flexibility, so it has the ability to absorb energy during impact. Due to its flexibility, the wings are supported by carbon fiber, fiberglass or balsa rods.

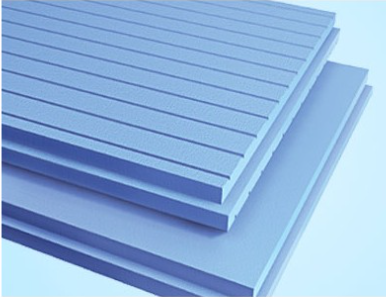

c) Xps Extruded Polystyren:

It has a completely closed cell structure. It helps the foam resist moisture penetration and water retention better than others. Such closed cell structure also contributes to the long-term durability and strength of the foam material. However, like many other foam materials, XPS foam is flammable. What we see in the pipa is blue, pink, purple foam.

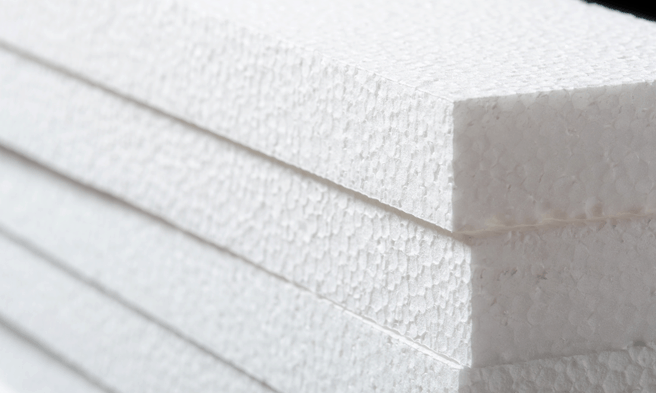

d) EPS (expended polystyrene)

It is known as expanded polystyrene. It is in the polystyrene family of thermoplastics. It is not very durable, it is quite fragile and care should be taken when cutting with hot wire or other utility knife. There may be dents with impacts during cutting. It can be glued immediately with C.A glue in case of a breakdown. Due to its structure, it may cause problems in painting. Water-based paints are therefore recommended. Depron also has very similar properties with eps.

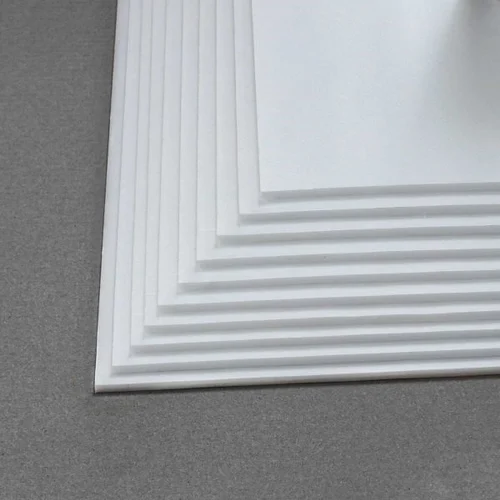

e) Depron -Photoblock

Depron has very similar properties with eps. The difference between photoblock and depron is often wondered by beginners. Photoblock is the form of depron with paper glued on its top and bottom. These papers give the depron extra weight and strength. We can reinforce depron with fiber tapes.

3) Filaments

Filaments are the raw material of thermoplastics. They are as important as dimensional printers. The most commonly used filament types in RC aircraft construction are PLA, ABS and carbon fiber. Building an RC airplane with a 3D printer requires a lot of time because it takes many hours. When making an RC airplane, attention should be paid to the center point of the aircraft and the places where the wing and fuselage meet, where the most momentum is, should be strengthened.

4) Carbon Fiber

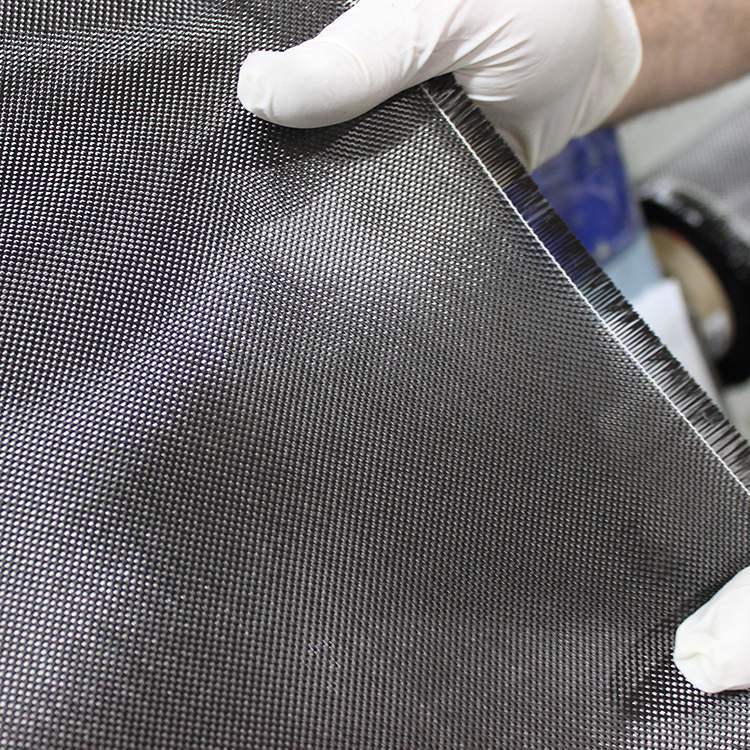

It is the most widely used composite in the aerospace industry. It is a strong, durable and lightweight fabric polymer material. It is more expensive than other materials. Aircraft construction with carbon fiber requires experience. The most commonly used part production method is hand lay-up with epoxy. The most common example of a carbon fiber part we see is the spar (wing support rod). Carbon fiber is used in the construction of spars. They usually use 3k carbon fiber. We can determine how many layers of carbon fiber we will use in analysis and design programs such as Ansys and Solidworks by making durability based analysis. When manufacturing the body with carbon fiber, it is necessary to pay attention to the devices inside the body that communicate with the signal.

5) Glass fiber (fiberglass)

One of the materials used in model airplanes and fixed-wing UAVs is glass fiber. It is a fabric made of thin strands. It is cheaper than carbon fiber. Its tensile stress is quite high due to its durability and flexible structure. Many types of styrofoam and balsa are used in airplanes to increase their strength by means of epoxy.